Vol. 9, Issue 6 (2021)

Splat morphology of WC-CO powder at different flow rate

Author(s): Dr. Shalu Tyagi

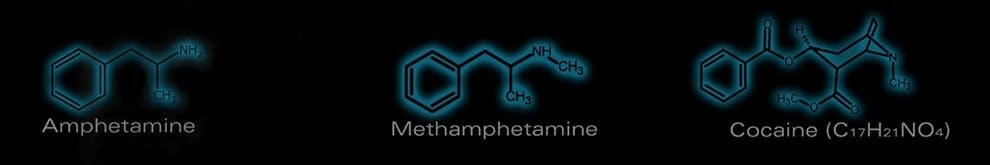

Abstract: Conventional Hard Chromium plating is produced from chromic acid solutions, which contain catalytic anions. Hard Chromium plating has as a main properties high hardness and resistance against corrosion. It has also a good wear behavior (abrasive and friction wear).Hard Chromium is widely applied in the engineering industry (aerospace, automotive, naval. etc.). The problem with Hard Chrome is not with the plated metal, but with the environmental problems associated with the plating process. Hard Chromium plating uses chromic acid, which releases fumes into the air during the plating process. This mist contains chromium +6 ions that are carcinogenic and can cause other medical problems, such as performed nasal passages and skin rashes. Due to these reasons the industries has enhanced the research of an alternative process for hard chromium coating. In this paper we studied that Hard Chromium. Thermal Spray Coatings, e.g., WC-Co is a possible substitute of Hard Chromium plating.

Pages: 77-83 | 393 Views 92 Downloads

download (9205KB)

How to cite this article:

Dr. Shalu Tyagi. Splat morphology of WC-CO powder at different flow rate. Int J Chem Stud 2021;9(6):77-83.